map

الجمعة، 18 ديسمبر 2020

السبت، 24 أكتوبر 2020

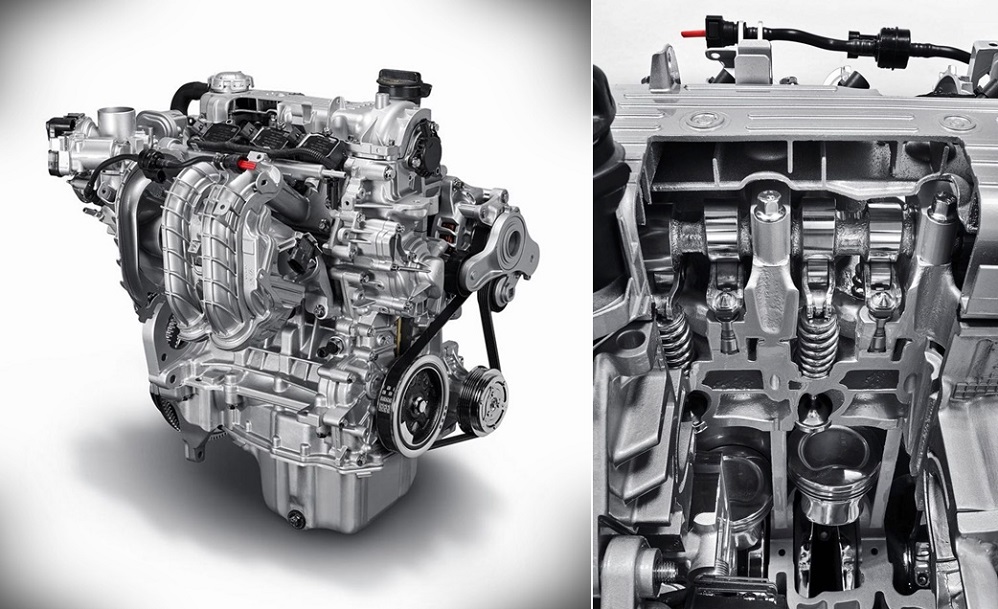

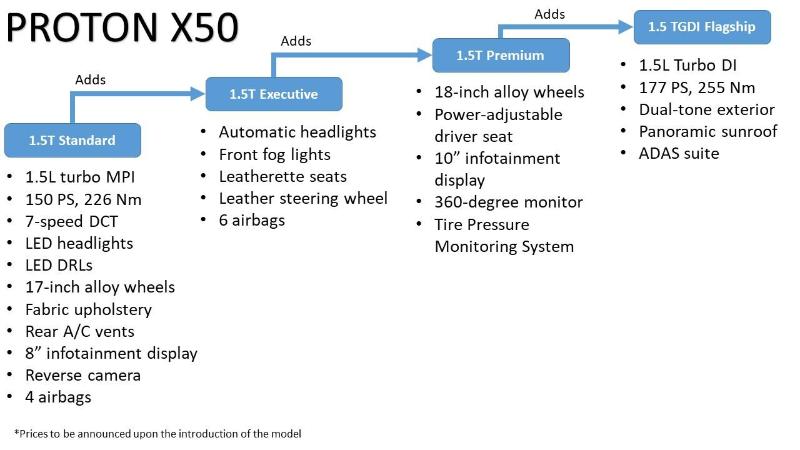

Proton The 1.5 TGDI unit, codename JLH-3G15TD, is co-developed by Geely and Volvo,Proton

☺

We’ve just received confirmation from Proton’s officials that the 2020 Proton X50 1.5T & 1.5 TGDi will both be 3-cylinders. Our earlier reports that indicates the 1.5-litre multi-port injection turbo engine is a 4-cylinder unit is incorrect. All articles have since been amended.

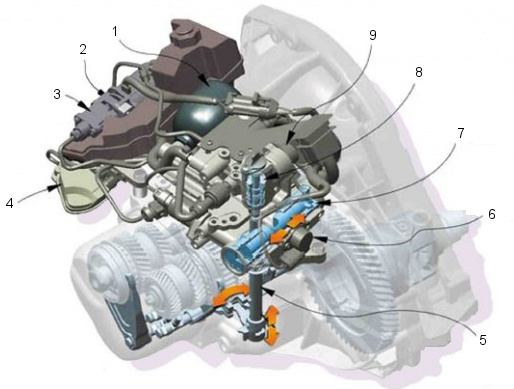

Proton will be offering two 1.5-litre turbocharged 3-cylinder engine options for the X50 the difference between them is the type of fuel system used. The lower output 1.5T unit uses a multi-port injection (MPI) while the 1.5 TGDI uses direct injection.

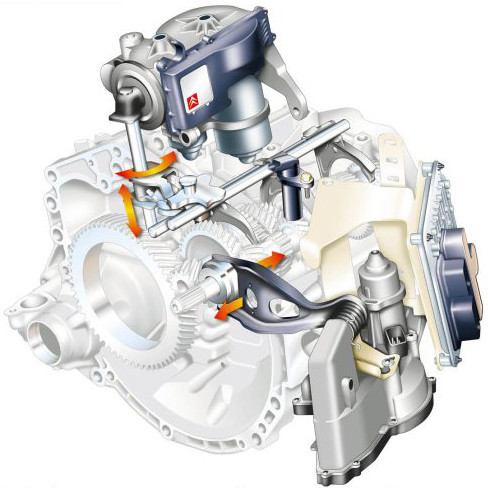

Both engine options are paired to the same 7-speed wet dual-clutch transmission first seen in the Proton X70 CKD. However, the 7DCT in the X50 will have a different calibration from the X70.

The 1.5 TGDI unit, codename JLH-3G15TD, is co-developed by Geely and Volvo. It develops 177 PS and 255 Nm of torque, making the X50 the most powerful car in its class.

However, there is very little info about the 1.5T as it is a new engine that will be making its debut in the X50. All we know that it will have 3-cylinders, a turbo, MPI, 7DCT, and makes 150 PS – the output figures we assure you, is accurate and verified by Proton.

Once again, we apologise for the misinformation.

الأربعاء، 16 سبتمبر 2020

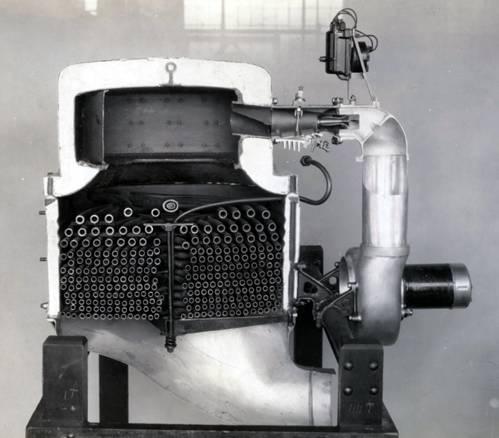

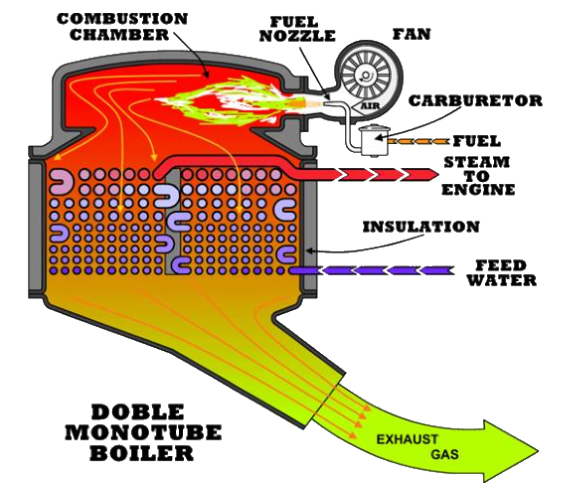

Doble Water Tube Boiler (monotube)Doble Steam Motors automobiles

♥

Doble Water Tube Boiler (monotube)Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler reached operating temperature and pressure in much less time than the Stanley. Doble imagesThe Doble is a once-through boiler, water entering one end and heat applied until emerging from the other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop, extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is only one tube for the water to pass through rather than a number of parallel tubes.*The small water volume provides little reserve power in excess of maximum steady state output.*Superheating in a tube only starts above the water level; minor level fluctuation changes the length of the portions generating and superheating steam, making accurate control difficult.*The peak firing rate is limited by DNB and a circulation ratio of 1. Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for generations and only relatively recently are we seeing a shift.

Doble Water Tube Boiler (monotube)Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler reached operating temperature and pressure in much less time than the Stanley. Doble imagesThe Doble is a once-through boiler, water entering one end and heat applied until emerging from the other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop, extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is only one tube for the water to pass through rather than a number of parallel tubes.*The small water volume provides little reserve power in excess of maximum steady state output.*Superheating in a tube only starts above the water level; minor level fluctuation changes the length of the portions generating and superheating steam, making accurate control difficult.*The peak firing rate is limited by DNB and a circulation ratio of 1. Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for generations and only relatively recently are we seeing a shift.

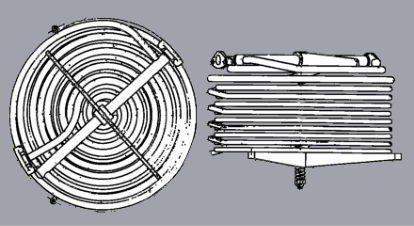

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a ‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next ‘pancake’ and then spirals outwards. See image o

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a ‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next ‘pancake’ and then spirals outwards. See image o

الخميس، 3 سبتمبر 2020

شركة دونج فينج الصينية ,مع شركة بروتون الماليزية

وقعت شركة النصر للسيارات المصرية، مذكرة تفاهم ، مع شركة دونج فينج الصينية، لتصنيع سيارات كهربائية في مصر، بحسب بيان من وزارة قطاع الأعمال العام المصرية، اليوم الخميس.

وقال هشام توفيق وزير قطاع الأعمال العام المصري، في البيان، إن المشروع بمثابة انطلاقة لصناعة السيارات الكهربائية في مصر، وبوابة لإدخال هذه التكنولوجيا في شمال أفريقيا.

خلفية عن شركة النصر

(بحسب موقع الشركة القابضة للصناعات المعدنية)

تأسست عام 1960، وهي من الشركات الحكومية التاريخية في مصر، مملوكة للشركة القابضة للصناعات المعدنية، التابعة لوزارة قطاع الأعمال العام.

ولا يزال مصنع الشركة موجود في منطقة حلوان بالقاهرة ولكنه متوقف عن العمل، بحسب موقع الشركة القابضة للصناعات المعدنية.

ويأتي تصنيع السيارات الكهربائية في مصر في إطار مشروع لإحياء شركة النصر للسيارات المتوقفة منذ صدور قرار تصفيتها عام 2009.

وكانت الشركة قبل توقفها تنتج سيارات وأوتوبيسات وجرارات زراعية، تحت العلامة التجارية (نصر).

وفي عام 2000 تم فصل نشاط تصنيع الأتوبيسات واللوري والجرارات الزراعية تحت مسمى الشركة الهندسية لصناعة السيارات، وهي أيضا تابعة لوزارة قطاع الأعمال العام.

خلفية عن شركة دونج فينج

(بحسب الموقع الإلكتروني للشركة)

تأسست عام 1969 ومقرها في مدينة ووهان، وهي واحدة من أكبر شركات السيارات في الصين.

وتعمل في إنتاج السيارات التقليدية وكذلك السيارات التي تعمل بالطاقة الجديدة، وقطع غيار السيارات ومكوناتها.

قالت وزارة قطاع الأعمال إن الاتفاقية مع الشركة الصينية لإنتاج سيارات كهربائية على خطوط شركة النصر للسيارات، بطاقة إنتاجية 25 ألف سيارة في السنة، وستحمل العلامة التجارية (النصر).

وذكر البيان أن وزارة قطاع الأعمال تستهدف الانتهاء من الدراسات الخاصة بالمشروع قبل نهاية صيف العام الجاري، وبدء الإنتاج قبل نهاية 2021.

وأضافت الوزارة أن الاتفاق ينص على إنتاج أحدث طرازات السيارات الكهربائية التي تنتجها شركة دونج فينج، وهي (E 70)، لأنها تتناسب مع السوق المصري، بحسب البيان.

كما تم الاتفاق على اختبار عدد محدود من السيارات من هذا الطراز في مصر خلال الفترة المقبلة.

حوافز لدعم صناعة السيارات الكهربائية

قال وزير قطاع الأعمال العام في البيان إن الحكومة ستقدم دعم قيمته 50 ألف جنيه (3 آلاف دولار) لأول 100 ألف مشتري للسيارات الكهربائية، وفق ضوابط محددة، لم يفصح عنها.

وأضاف أنه سيتم إنشاء 3 آلاف محطة شحن كهرباء سريع للسيارات على مدار 3 سنوات، ومشروع لإحلال التاكسي الأبيض في القاهرة بسيارات كهربائية أسوة بمشروع إحلال التاكسي الأبيض بدلا من التاكسي التقليدي في عام 2008.

خلفية عن اتفاقية أخرى

كانت الشركة القابضة للصناعات المعدنية، أعلنت قبل يومين في بيان عن توقيع مذكرة تفاهم أخرى مع شركة بروتون الماليزية، المصنعة للسيارات، من أجل إنتاج نحو 20 ألف سيارة تقليدية في شركة النصر للسيارات أيضا.

الأحد، 3 مايو 2020

range rover sedan 2020

range rover sedan 2020

الخميس، 16 أبريل 2020

Fiat to build two cylinder SGE engine in Poland,The technology combines the latest 3-cylinder FireFly 1-litre

Hybrid Technology In 2020 Fiat 500 And Panda Begins Electrification Of Italian Brand

Furthermore, for the first time in the history of the two iconic and complementary Fiat brand models, the 500 and the Panda will be available in a special unique series: the exclusive ‘Launch Edition’. The special series can be recognized by the ‘Hybrid’ badge on the rear and the exclusive ‘H’ logo, formed by two dew drops, on the centre panel.

On the inside, the seat upholstery is faithful to the sustainable philosophy of the entire project. The Launch Edition seats are the first in the automotive sector to be partly made with SEAQUAL YARN, the weaving of which produces a special material derived from recycled plastic. SEAQUAL YARN is produced by transforming plastics collected from the sea into flakes of polyethylene terephthalate. These flakes are then used in the yarn from which the fabrics are made.

2020 also marks the new milestone in the history of the Fiat brand. With the launch of the new hybrid versions of the 500 and Panda, the electrification of the brand will begin, and will continue with the start of production in Turin of the new 500. This model will be 100% electric and therefore play a key role in the e-Mobility by FCA strategy.

Fiat to build two cylinder SGE engine in Poland

الثلاثاء، 31 مارس 2020

how is Koenigsegg going to top this level of engineering geekery?

Getting 150-200bhp from a 3-cylinder engine is fairly normal these days, but how about triple that figure?! Koenigsegg recently released the Gemera – the first ever four-seater hypercar – and while it develops 1,700bhp in total, the most remarkable thing is that 600bhp of that comes from a 3-cylinder engine. As always, Christian von Koenigsegg has been as innovative as ever.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19773191/Screen_Shot_2020_03_06_at_1.01.36_PM.png)

السبت، 22 فبراير 2020

battery-powered CSACs with 1000x improvement in key performance parameters over existing options.

DARPA Making Progress on Miniaturized Atomic Clocks for Future PNT Applications

Researchers on the ACES program show early signs of success in developing chip-scale atomic clocks with 1000x performance improvements

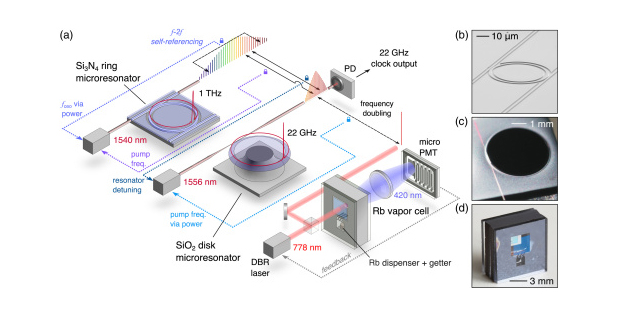

Figure 1. Schematic of the microfabricated photonic optical atomic clock developed by NIST, California Institute of Technology, Stanford University, and Charles Stark Draper Laboratories. Source: NIST

Figure 2. Silicon chip with waveguides and gratings to create a 3D laser beam pattern. In the photo, the light-guiding channels glow from the light they are directing, and the invisible 3D beams coming out of the chip are indicated by a computer-rendered overlay. Source: Honeywell

Figure 3. This photo is of the ACES 10 cc package developed by researchers from NASA’s JPL. Source: NASA Jet Propulsion Laboratory

الخميس، 20 فبراير 2020

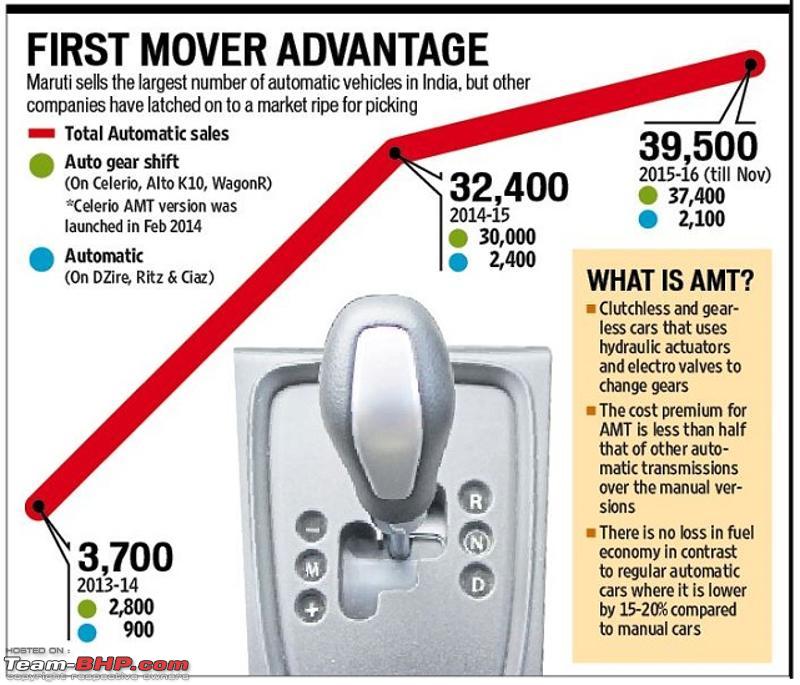

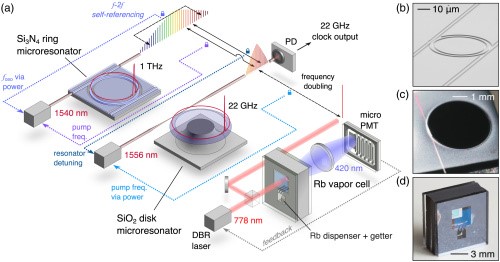

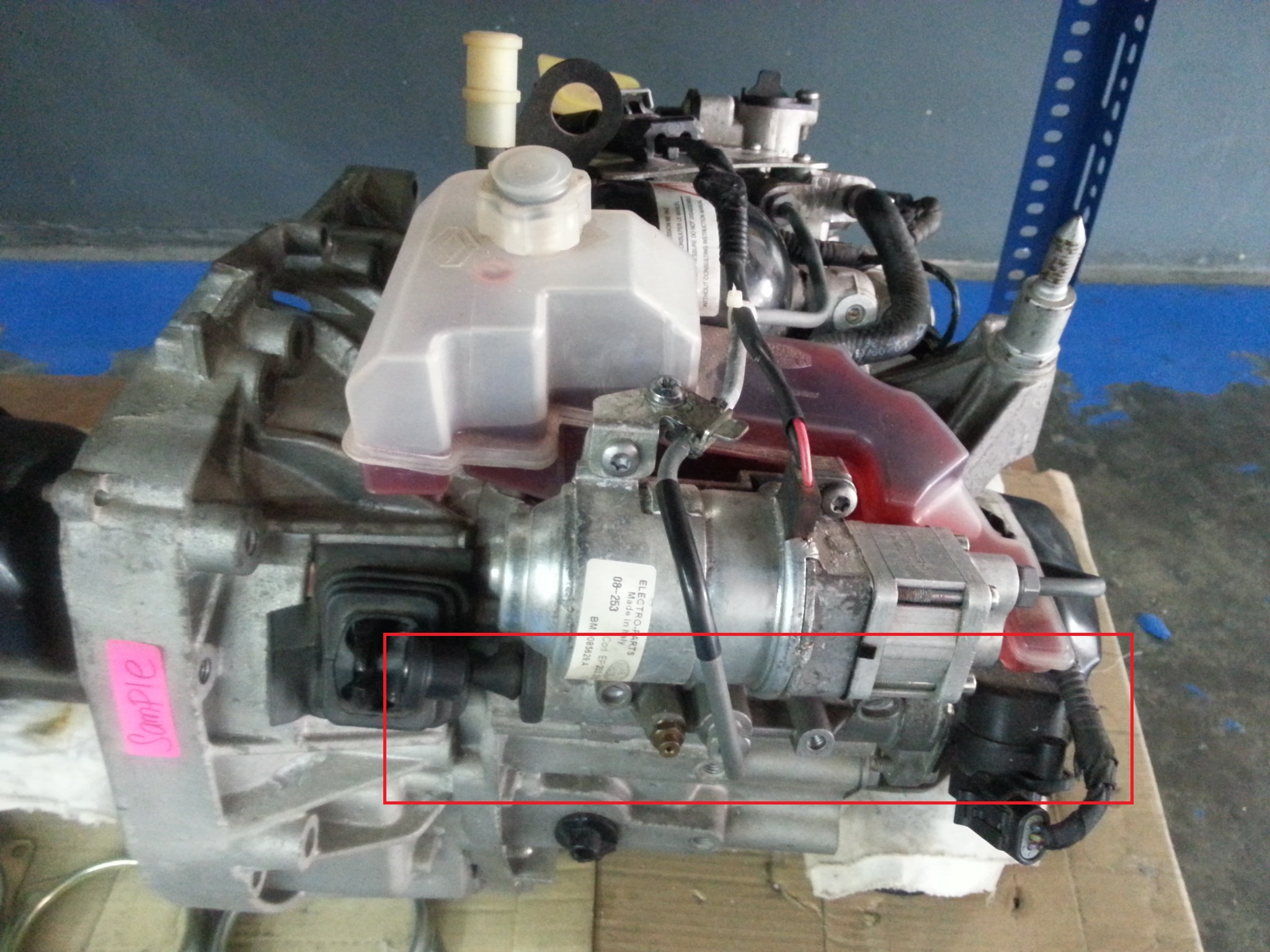

هو الافضل لمصر لاءنخفاض مصاريف وتكلفة الصيانة وايضا سهولة الصيانة !! فتيس اوتوماتيك AMT

بالنسبة لاءفضل فتيس اوتوماتيك مناسب لمصر هو فتيس AMT

افضل كتير من الفيس

CVT او DCTاو DSG

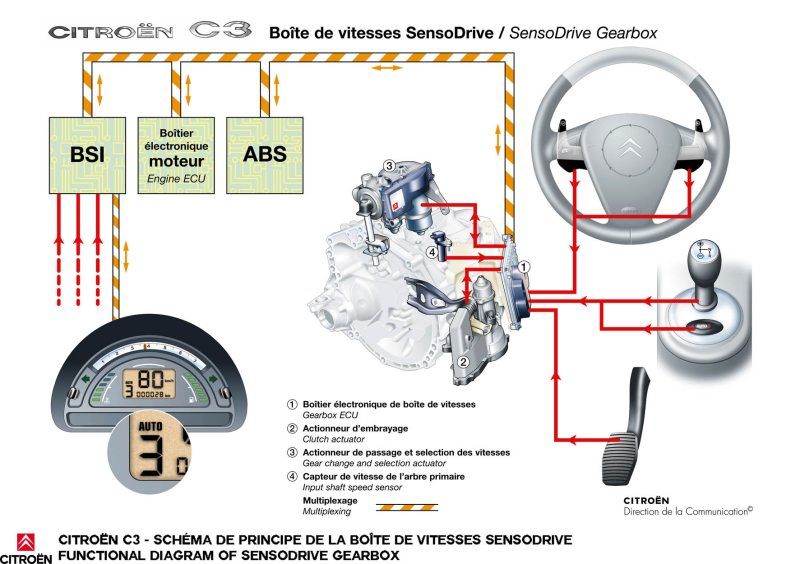

AMT (Automated Manual Transmission)

What is an AMT transmission?

Which cars offer the AMT transmission?

What are the modes of operation available in an AMT gearbox?

Are there any other differences between AMT and traditional automatic gearbox?

Which are the different companies that develop the AMT gearbox?